Process Introduction

-

-

Service IndustryOil and gas, food, chemicals and other liquid measurement controlWe have focused on the measurement and control industry in the parts investment precision industry for nearly 40 years. With an efficient and highly competitive one-stop solution, we can meet the ever-changing needs of customers who are global industry leaders.

Steam generator setWe have a professional team to provide the whole process service of static blades for the largest steam turbine customers in China, from mold design and production to blank production, polishing, processing and inspection to finished products.

Steam generator setWe have a professional team to provide the whole process service of static blades for the largest steam turbine customers in China, from mold design and production to blank production, polishing, processing and inspection to finished products. AerospaceHao Sen can provide a variety of casting processes and precision machining technology to produce aerospace components that meet industry standards and customer requirements. And a full range of testing services to ensure product quality. Providing customers with one-stop solutions enables us to guarantee competitive prices, timely delivery and high quality of products.

AerospaceHao Sen can provide a variety of casting processes and precision machining technology to produce aerospace components that meet industry standards and customer requirements. And a full range of testing services to ensure product quality. Providing customers with one-stop solutions enables us to guarantee competitive prices, timely delivery and high quality of products. High speed centrifugeCentrifuge industry is a product precision, high performance requirements, complex structure. Hao Sen can not only provide customers with production services, but also provide a full set of one-stop inspection solutions such as dynamic balance.

High speed centrifugeCentrifuge industry is a product precision, high performance requirements, complex structure. Hao Sen can not only provide customers with production services, but also provide a full set of one-stop inspection solutions such as dynamic balance. Food MachineryThe surface of food machinery products is required to meet the Ra0.4 mirror standard, the product is difficult to polish, and the salt spray test of the polished product requires a 48-hour neutral salt spray test. Hao Sen customers can provide all internal processes to meet customer requirements.

Food MachineryThe surface of food machinery products is required to meet the Ra0.4 mirror standard, the product is difficult to polish, and the salt spray test of the polished product requires a 48-hour neutral salt spray test. Hao Sen customers can provide all internal processes to meet customer requirements. OtherSupport, cylinder, piston rod: Hao Sen customers produce precision products under various environmental requirements according to customer requirements.

OtherSupport, cylinder, piston rod: Hao Sen customers produce precision products under various environmental requirements according to customer requirements.

-

-

3D printing3D printing is used for new product development, which shortens the research and development cycle, saves the mold opening, and provides delivery guarantee for the research and development of new products cast by Haosen.

Mold manufacturingThe mold department is the first step in the production process of our company's products. The mold department currently has 27 people, and has complete processes such as design, process, turning, milling, grinding, CNC, three-coordinate, electric spark, wire cutting, fine boring, fitter, etc., which can fully independent the whole process of mold and tooling design and production assembly. Design and processing personnel experience, working time are more than 10 years. Manufacturing and production products, involving: precision casting molds, small blanking molds, rubber molds, plastic molds, parts processing tooling, measuring tools, aerospace supporting products molds and tooling.

Mold manufacturingThe mold department is the first step in the production process of our company's products. The mold department currently has 27 people, and has complete processes such as design, process, turning, milling, grinding, CNC, three-coordinate, electric spark, wire cutting, fine boring, fitter, etc., which can fully independent the whole process of mold and tooling design and production assembly. Design and processing personnel experience, working time are more than 10 years. Manufacturing and production products, involving: precision casting molds, small blanking molds, rubber molds, plastic molds, parts processing tooling, measuring tools, aerospace supporting products molds and tooling. Investment CastingsInvestment casting is one of the complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts.

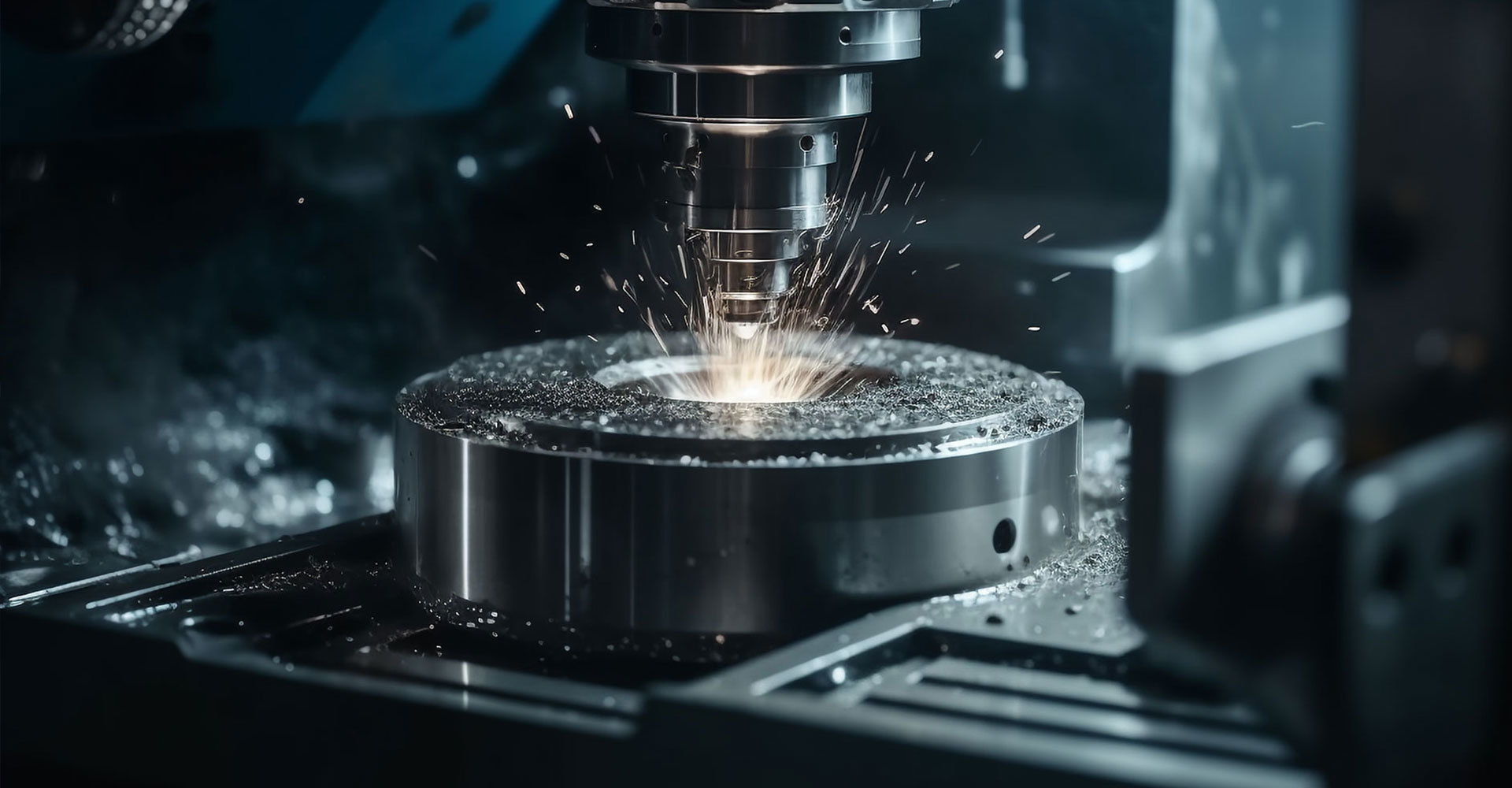

Investment CastingsInvestment casting is one of the complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts. Precision MachiningPrecision machining is the application of production processes including turning, milling, boring, drilling, EDM, engraving, grinding and other processes, through mechanical processing to remove the material on the workpiece, the production of drawings with strict dimensional accuracy and shape tolerance and high surface quality of precision parts process.

Precision MachiningPrecision machining is the application of production processes including turning, milling, boring, drilling, EDM, engraving, grinding and other processes, through mechanical processing to remove the material on the workpiece, the production of drawings with strict dimensional accuracy and shape tolerance and high surface quality of precision parts process.

-

-

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

中文 | EN

Investment Castings

Investment Castings

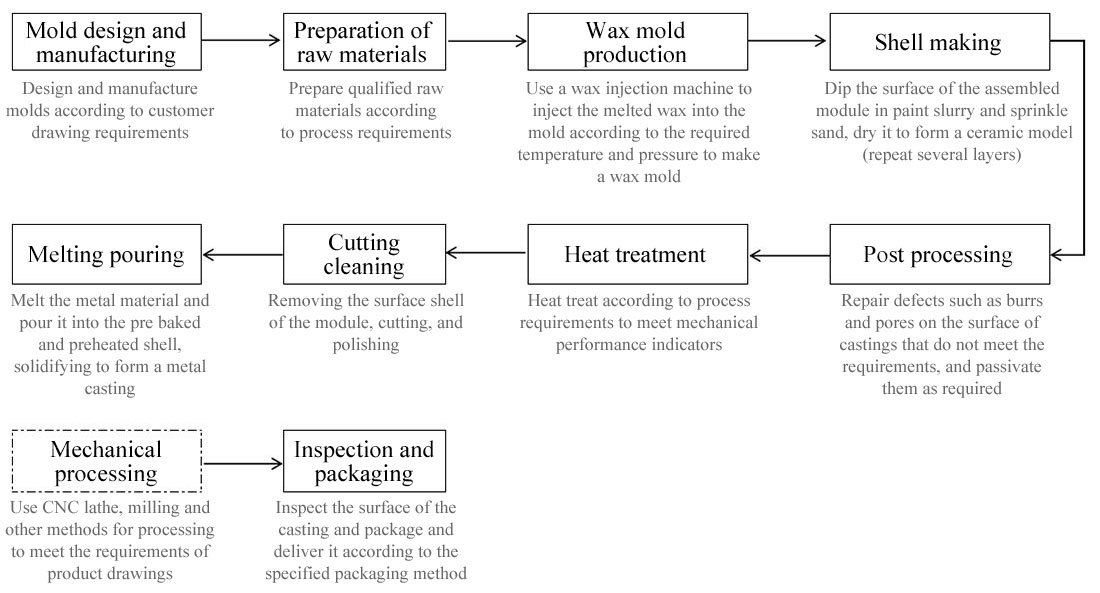

Investment casting is one of the most complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts. Investment casting can be used to produce almost all metal material products to meet the needs of a wide range of end markets. Investment casting is a metal forming process in which ceramic heat-resistant materials are coated on the surface of the wax mold to form a ceramic mold, and the formed ceramic mold is dried and melted to remove the wax mold to form a mold shell. Then, molten metal is poured into the ceramic mold shell, and the mold shell is removed after the metal is formed, thereby obtaining a casting. Some investment castings require post-processing after casting. The investment casting process is often used to produce parts with complex shapes and high dimensional accuracy and surface quality requirements.

Process Flow Diagram of Investment Casting

Equipment

The production of high-complexity, high-precision investment castings requires high-quality equipment that must be able to achieve tight tolerances and repeatable accuracy. At the same time, production equipment and manufacturing processes must also be able to handle large quantities of products quickly and continuously without compromising product quality. At Haosen Precision Casting, we use more advanced technology and cutting-edge equipment at all stages of the investment casting process. Mold design, wax pressing, wax module tree, shell making, pouring, heat treatment and testing are all done by our professional team using the best equipped equipment.

Wax Pressing

Hao Sen Precision Casting has 19 fully automatic and semi-automatic wax pressing machines. Among them, there are 11 8T double-station wax injection machines, 1 10T wax injection machine, 1 16T wax injection machine, 3 25T wax injection machines, 1 30T wax injection machine, 1 50T wax injection machine and 1 80T wax injection machine, which meet the pressing needs of products of different sizes.

Shell Making

Haosen Precision Casting has two shell-making production lines, manual shell-making lines and automatic shell-making lines. The automatic shell-making line introduces the domestic advanced three-head and six-arm dipping slurry and sand leaching machine, and the automatic production eliminates the difference in the quality of the mold shell that may occur in manual operation, improves the stability of the shell-making process, and reduces the manual work intensity.

Melting and Pouring

We have 17 medium frequency melting furnaces for steel casting production. In addition, we are equipped with two vacuum induction melting furnaces: a 25kg single-chamber vacuum furnace and a 50/100kg three-chamber vacuum furnace. These vacuum induction melting furnaces can cast nickel-based and cobalt-based investment castings in equiaxed solidification structures, weighing 0.02 to 150kg.

Materials

We can meet the requirements of various material specifications such as ASTM, AISI, DIN, EN, ISO and GB, and have the casting ability to produce hundreds of black and non-ferrous alloy materials including stainless steel, copper alloy, high temperature alloy, carbon steel, etc.

|

Martensitic stainless steel • ZG1Cr13 • ZG12Cr13 • ZG2Cr13 • ZG1Cr11MoV |

Austenitic stainless steel • 304304L • CF3 • CF3M • CF8M • CF8 • 1.4308 |

|

|

Precipitation hardening stainless steel • 17-4PH |

High temperature alloy • K4169 • K640 • K3625 • K418B |

|

|

Hastelloy • CX2MW • CW12MW • C22 • CW6M |

||

Ability

We have the ability to produce hundreds of black and non-ferrous alloy materials, including stainless steel, alloy steel, copper alloy superalloy, carbon steel, etc., to meet the requirements of various material specifications such as ASTM, AISI, DIN, EN, ISO and GB, as well as to meet the special material requirements of customers. We mainly produce investment castings with high dimensional tolerances and complex shapes, with single weights ranging from a few grams to 150 kg.

3D printing technology

3D printing technology is a cost-effective solution for rapid prototyping of samples and small batch production of workpieces. At Haosen, we use 3D printing to develop complex investment castings where the design needs to be perfected or the lead time is tight. 3D printing does not require mold opening, speeding up the design and verification of the casting process, which can shorten the overall product development cycle.

Why choose the 3D printing technology?

We are a comprehensive one-stop solution provider of high-tech components. We can provide a variety of value-added services on our own:

• Full set of dimensional inspection and metallurgical analysis capabilities

• Scanning technology

• Non-destructive testing (X-ray testing, stain testing, magnetic particle testing, fluorescent penetrant testing)

• Three-coordinate detection

• Heat treatment

• Surface treatment

• Comprehensive machining and assembly capabilities

Join hands with us, you'll get streamlined supply chain management, fast product delivery, lower procurement costs, and assured, on-time quality service.

3D printing equipment: EP-S7250

Maximum size: 600 x 600 x 600 mm

Materials commonly used in 3D printing: polystyrene (PS) powder. The choice of material depends on the requirements of the mould.

Typical investment castings produced using 3D technology:

Address: No.28, Lantian 1st Road, National Aviation High-tech Industrial Base, Yanliang District, Xi'an City, Shaanxi Province

+86029-89080114 13630258521

Copyright©2023 Xi'an Haosen Precision Casting Co., Ltd.

Technical Support:China Enterprise Power Xi'an

SAF Coolest v1.3 设置面板 GAYSX-ZENJ-FFZQE-ZES

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page