-

-

Service IndustryOil and gas, food, chemicals and other liquid measurement controlWe have focused on the measurement and control industry in the parts investment precision industry for nearly 40 years. With an efficient and highly competitive one-stop solution, we can meet the ever-changing needs of customers who are global industry leaders.

Steam generator setWe have a professional team to provide the whole process service of static blades for the largest steam turbine customers in China, from mold design and production to blank production, polishing, processing and inspection to finished products.

Steam generator setWe have a professional team to provide the whole process service of static blades for the largest steam turbine customers in China, from mold design and production to blank production, polishing, processing and inspection to finished products. AerospaceHao Sen can provide a variety of casting processes and precision machining technology to produce aerospace components that meet industry standards and customer requirements. And a full range of testing services to ensure product quality. Providing customers with one-stop solutions enables us to guarantee competitive prices, timely delivery and high quality of products.

AerospaceHao Sen can provide a variety of casting processes and precision machining technology to produce aerospace components that meet industry standards and customer requirements. And a full range of testing services to ensure product quality. Providing customers with one-stop solutions enables us to guarantee competitive prices, timely delivery and high quality of products. High speed centrifugeCentrifuge industry is a product precision, high performance requirements, complex structure. Hao Sen can not only provide customers with production services, but also provide a full set of one-stop inspection solutions such as dynamic balance.

High speed centrifugeCentrifuge industry is a product precision, high performance requirements, complex structure. Hao Sen can not only provide customers with production services, but also provide a full set of one-stop inspection solutions such as dynamic balance. Food MachineryThe surface of food machinery products is required to meet the Ra0.4 mirror standard, the product is difficult to polish, and the salt spray test of the polished product requires a 48-hour neutral salt spray test. Hao Sen customers can provide all internal processes to meet customer requirements.

Food MachineryThe surface of food machinery products is required to meet the Ra0.4 mirror standard, the product is difficult to polish, and the salt spray test of the polished product requires a 48-hour neutral salt spray test. Hao Sen customers can provide all internal processes to meet customer requirements. OtherSupport, cylinder, piston rod: Hao Sen customers produce precision products under various environmental requirements according to customer requirements.

OtherSupport, cylinder, piston rod: Hao Sen customers produce precision products under various environmental requirements according to customer requirements.

-

-

3D printing3D printing is used for new product development, which shortens the research and development cycle, saves the mold opening, and provides delivery guarantee for the research and development of new products cast by Haosen.

Mold manufacturingThe mold department is the first step in the production process of our company's products. The mold department currently has 27 people, and has complete processes such as design, process, turning, milling, grinding, CNC, three-coordinate, electric spark, wire cutting, fine boring, fitter, etc., which can fully independent the whole process of mold and tooling design and production assembly. Design and processing personnel experience, working time are more than 10 years. Manufacturing and production products, involving: precision casting molds, small blanking molds, rubber molds, plastic molds, parts processing tooling, measuring tools, aerospace supporting products molds and tooling.

Mold manufacturingThe mold department is the first step in the production process of our company's products. The mold department currently has 27 people, and has complete processes such as design, process, turning, milling, grinding, CNC, three-coordinate, electric spark, wire cutting, fine boring, fitter, etc., which can fully independent the whole process of mold and tooling design and production assembly. Design and processing personnel experience, working time are more than 10 years. Manufacturing and production products, involving: precision casting molds, small blanking molds, rubber molds, plastic molds, parts processing tooling, measuring tools, aerospace supporting products molds and tooling. Investment CastingsInvestment casting is one of the complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts.

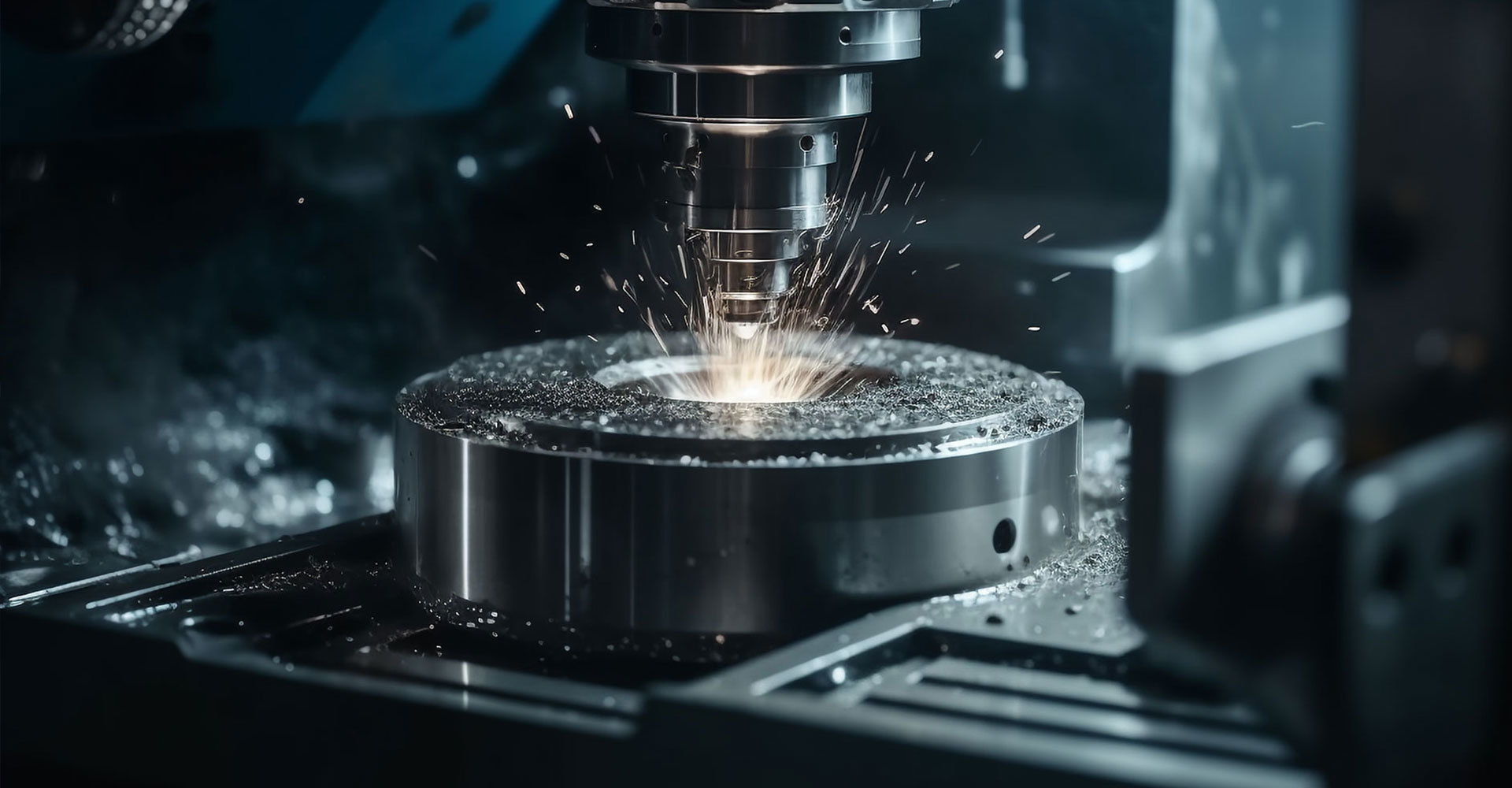

Investment CastingsInvestment casting is one of the complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts. Precision MachiningPrecision machining is the application of production processes including turning, milling, boring, drilling, EDM, engraving, grinding and other processes, through mechanical processing to remove the material on the workpiece, the production of drawings with strict dimensional accuracy and shape tolerance and high surface quality of precision parts process.

Precision MachiningPrecision machining is the application of production processes including turning, milling, boring, drilling, EDM, engraving, grinding and other processes, through mechanical processing to remove the material on the workpiece, the production of drawings with strict dimensional accuracy and shape tolerance and high surface quality of precision parts process.

-

-

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

中文 | EN

Automation

Automation

A tributary and automation:

Tracking components from start to finish, maintaining strict inventory, and reducing delivery time from 5-8 weeks to 3-4 weeks, we combine advanced processes, extensive flow and automation to provide you with better service. From the moment you ask us for a quote, with our leading DC and automation, to provide you with better service.

Faster delivery time full control:

In order to meet your delivery date, we usually advance the order date by a few days as the final delivery date, even if there is a risk, we can respond in a timely manner.

Quotation stage:From the identification of drawings to the arrangement of quotation information, full communication and record, and deliver the quotation to the customer within 3 days or less.

Development phase:Have professional engineering personnel to determine product quality, delivery standard, delivery date, delivery data, etc.

Production stage:We monitor all aspects of the project-personnel, equipment, status, inventory, in the system;

Logistics delivery:The information from quotation to delivery is completely complete, the perfection of ppap data and the packaging protection of samples, has been monitoring it to your loading and unloading.

Better control and coordination:

We have professional engineers to make inquiry drawings, analyze and identify material specifications, batch size, appearance status, product use environment, special testing items, etc. to establish relevant information for communication and confirmation at any time. Each process of the product can collect relevant information through the system at any time to grasp the progress and quality information status of the product at any time. We will refine the nodes of each product to the day, the production process and process conditions can be delivered in time to track parts to ensure that all stages of the product are in a controllable state to ensure customer quality and delivery.

Shorten the order cycle, timely delivery, no excess inventory:

We establish long-term inventory agreements with customers to ensure that inventory is at the highest and lowest water levels, and customers can pull demand at any time to ensure accurate, on-time delivery and product supply.

Address: No.28, Lantian 1st Road, National Aviation High-tech Industrial Base, Yanliang District, Xi'an City, Shaanxi Province

+86029-89080114 13630258521

Copyright©2023 Xi'an Haosen Precision Casting Co., Ltd.

Technical Support:China Enterprise Power Xi'an

SAF Coolest v1.3 设置面板 GAYSX-ZENJ-FFZQE-ZES

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page