-

-

Service IndustryOil and gas, food, chemicals and other liquid measurement controlWe have focused on the measurement and control industry in the parts investment precision industry for nearly 40 years. With an efficient and highly competitive one-stop solution, we can meet the ever-changing needs of customers who are global industry leaders.

Steam generator setWe have a professional team to provide the whole process service of static blades for the largest steam turbine customers in China, from mold design and production to blank production, polishing, processing and inspection to finished products.

Steam generator setWe have a professional team to provide the whole process service of static blades for the largest steam turbine customers in China, from mold design and production to blank production, polishing, processing and inspection to finished products. AerospaceHao Sen can provide a variety of casting processes and precision machining technology to produce aerospace components that meet industry standards and customer requirements. And a full range of testing services to ensure product quality. Providing customers with one-stop solutions enables us to guarantee competitive prices, timely delivery and high quality of products.

AerospaceHao Sen can provide a variety of casting processes and precision machining technology to produce aerospace components that meet industry standards and customer requirements. And a full range of testing services to ensure product quality. Providing customers with one-stop solutions enables us to guarantee competitive prices, timely delivery and high quality of products. High speed centrifugeCentrifuge industry is a product precision, high performance requirements, complex structure. Hao Sen can not only provide customers with production services, but also provide a full set of one-stop inspection solutions such as dynamic balance.

High speed centrifugeCentrifuge industry is a product precision, high performance requirements, complex structure. Hao Sen can not only provide customers with production services, but also provide a full set of one-stop inspection solutions such as dynamic balance. Food MachineryThe surface of food machinery products is required to meet the Ra0.4 mirror standard, the product is difficult to polish, and the salt spray test of the polished product requires a 48-hour neutral salt spray test. Hao Sen customers can provide all internal processes to meet customer requirements.

Food MachineryThe surface of food machinery products is required to meet the Ra0.4 mirror standard, the product is difficult to polish, and the salt spray test of the polished product requires a 48-hour neutral salt spray test. Hao Sen customers can provide all internal processes to meet customer requirements. OtherSupport, cylinder, piston rod: Hao Sen customers produce precision products under various environmental requirements according to customer requirements.

OtherSupport, cylinder, piston rod: Hao Sen customers produce precision products under various environmental requirements according to customer requirements.

-

-

3D printing3D printing is used for new product development, which shortens the research and development cycle, saves the mold opening, and provides delivery guarantee for the research and development of new products cast by Haosen.

Mold manufacturingThe mold department is the first step in the production process of our company's products. The mold department currently has 27 people, and has complete processes such as design, process, turning, milling, grinding, CNC, three-coordinate, electric spark, wire cutting, fine boring, fitter, etc., which can fully independent the whole process of mold and tooling design and production assembly. Design and processing personnel experience, working time are more than 10 years. Manufacturing and production products, involving: precision casting molds, small blanking molds, rubber molds, plastic molds, parts processing tooling, measuring tools, aerospace supporting products molds and tooling.

Mold manufacturingThe mold department is the first step in the production process of our company's products. The mold department currently has 27 people, and has complete processes such as design, process, turning, milling, grinding, CNC, three-coordinate, electric spark, wire cutting, fine boring, fitter, etc., which can fully independent the whole process of mold and tooling design and production assembly. Design and processing personnel experience, working time are more than 10 years. Manufacturing and production products, involving: precision casting molds, small blanking molds, rubber molds, plastic molds, parts processing tooling, measuring tools, aerospace supporting products molds and tooling. Investment CastingsInvestment casting is one of the complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts.

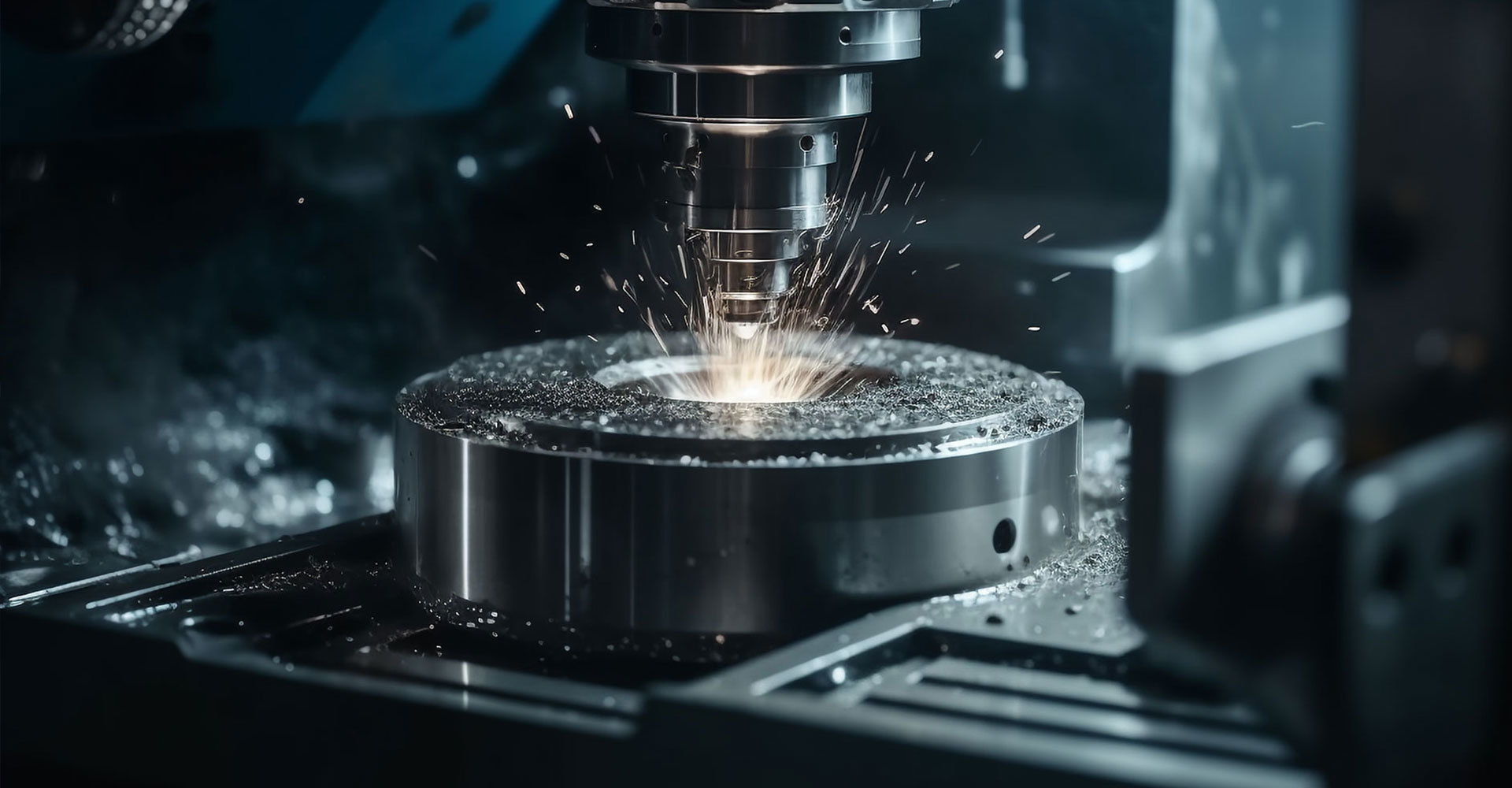

Investment CastingsInvestment casting is one of the complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts. Precision MachiningPrecision machining is the application of production processes including turning, milling, boring, drilling, EDM, engraving, grinding and other processes, through mechanical processing to remove the material on the workpiece, the production of drawings with strict dimensional accuracy and shape tolerance and high surface quality of precision parts process.

Precision MachiningPrecision machining is the application of production processes including turning, milling, boring, drilling, EDM, engraving, grinding and other processes, through mechanical processing to remove the material on the workpiece, the production of drawings with strict dimensional accuracy and shape tolerance and high surface quality of precision parts process.

-

-

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

中文 | EN

Why choose Haosen

Why choose Haosen

Fast market entry:

Through continuous lean improvement, we eliminate process waiting time, continuously improve the value-added part of the production line, and shorten the production cycle. We solemnly promise to our customers that within a reasonable production cycle, we guarantee that 100% of the time will be delivered according to the customer's requirements. In less than a reasonable period, we will also meet the customer's delivery needs. Based on this, we continue to balance the process capacity, eliminate the bottleneck process, the implementation of the "one tributary" lean production concept. We have established a precision casting production chain integrating self-mold design and manufacturing, investment precision casting, and CNC machining, which can respond quickly to meet the urgent needs of customer orders. While meeting the order delivery date, we also implement the "JIT" production organization concept and resolutely eliminate unnecessary waste caused by premature production.

Our goal is to bring our products to market quickly, so we are willing to accept any challenge:

The company has established a corporate vision of "contributing to industry development and social progress through the development and application of precision casting technology. We deeply know that science and technology are the primary productive forces, and technology is the source of power to promote the development of enterprises. Therefore, we continue to increase the investment in technology software and hardware. The company has more than 30 professional and technical personnel and has established an engineering technology research center. The technical principle of "profit, quality and efficiency are all designed" is reflected through continuous technical improvement and technological breakthrough, so as to continuously reduce costs, improve quality, improve efficiency, better serve customers, and contribute to the industry and society.

Making the best products:

Hao Sen's products: We are a first-class casting scheme provider. When customers encounter technical problems and difficulties, we can choose Hao Sen. We can provide first-class product design scheme, and use casting process simulation software to simulate the pouring system, fully evaluate and demonstrate the design scheme. At the same time, 3D printing technology is adopted to replace the traditional mold manufacturing time in the development stage of new products, thus greatly shortening the development cycle, at the same time, Hao Sen has established a perfect quality management system and a complete testing system to escort product development and production. To provide customers with a full range of precision casting solutions.

In the face of unprecedented high-quality output, we have the courage to accept the challenge:

Quality is the foundation of our survival and the cornerstone of enterprise development. Fully meeting the technical quality requirements of customers is our minimum requirement. We must continue to exceed customer expectations while meeting customer quality requirements. To this end, the company has established a scientific and complete quality management system, equipped with complete testing in the precision casting industry Equipment, trained quality personnel who are proficient in various standards. Striving for perfection and continuous innovation is our quality concept and our solemn commitment to our customers. Product is the character, we through the manufacture of perfect products to interpret our concept of life.

Solve your toughest design problems:

We have more than 30 in-house engineers to communicate with you in real time on every project to make your products reach the highest quality.

We take a hands-on approach to help you identify and improve potential efficiencies, achieve greater cost savings, and make product improvements, including:

• Better manufacturability

• Reduced assembly costs

• Elimination of secondary operations

• Shorten design time

• Enhanced product functionality.

Faced with unprecedented problems, we accept the challenge to provide the following:

Conventional precision metal manufacturing time cycle, weeks or even months, competitive market under the conventional production is difficult to meet the market demand and product replacement, and how to adapt to market demand to shorten the production cycle?

We believe that the key to investment casting is to make full use of its flexible functions and incorporate as much value as possible into the castings, because we will provide you with a better investment casting production plan. For the launch of new products, we provide more Accurate delivery time, high-quality prenatal preparation to meet your product release time.

We provide lean production planning and capacity analysis for small, medium and large volume operations according to your product schedule to achieve true no inventory and timely delivery.

Innovation standards-our experts are not imitating, but in constant innovation.

Our in-house operations will provide you with a full range of project services, including machining, heat treatment, and final finishing.

Address: No.28, Lantian 1st Road, National Aviation High-tech Industrial Base, Yanliang District, Xi'an City, Shaanxi Province

+86029-89080114 13630258521

Copyright©2023 Xi'an Haosen Precision Casting Co., Ltd.

Technical Support:China Enterprise Power Xi'an

SAF Coolest v1.3 设置面板 GAYSX-ZENJ-FFZQE-ZES

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page