-

-

Service IndustryOil and gas, food, chemicals and other liquid measurement controlWe have focused on the measurement and control industry in the parts investment precision industry for nearly 40 years. With an efficient and highly competitive one-stop solution, we can meet the ever-changing needs of customers who are global industry leaders.

Steam generator setWe have a professional team to provide the whole process service of static blades for the largest steam turbine customers in China, from mold design and production to blank production, polishing, processing and inspection to finished products.

Steam generator setWe have a professional team to provide the whole process service of static blades for the largest steam turbine customers in China, from mold design and production to blank production, polishing, processing and inspection to finished products. AerospaceHao Sen can provide a variety of casting processes and precision machining technology to produce aerospace components that meet industry standards and customer requirements. And a full range of testing services to ensure product quality. Providing customers with one-stop solutions enables us to guarantee competitive prices, timely delivery and high quality of products.

AerospaceHao Sen can provide a variety of casting processes and precision machining technology to produce aerospace components that meet industry standards and customer requirements. And a full range of testing services to ensure product quality. Providing customers with one-stop solutions enables us to guarantee competitive prices, timely delivery and high quality of products. High speed centrifugeCentrifuge industry is a product precision, high performance requirements, complex structure. Hao Sen can not only provide customers with production services, but also provide a full set of one-stop inspection solutions such as dynamic balance.

High speed centrifugeCentrifuge industry is a product precision, high performance requirements, complex structure. Hao Sen can not only provide customers with production services, but also provide a full set of one-stop inspection solutions such as dynamic balance. Food MachineryThe surface of food machinery products is required to meet the Ra0.4 mirror standard, the product is difficult to polish, and the salt spray test of the polished product requires a 48-hour neutral salt spray test. Hao Sen customers can provide all internal processes to meet customer requirements.

Food MachineryThe surface of food machinery products is required to meet the Ra0.4 mirror standard, the product is difficult to polish, and the salt spray test of the polished product requires a 48-hour neutral salt spray test. Hao Sen customers can provide all internal processes to meet customer requirements. OtherSupport, cylinder, piston rod: Hao Sen customers produce precision products under various environmental requirements according to customer requirements.

OtherSupport, cylinder, piston rod: Hao Sen customers produce precision products under various environmental requirements according to customer requirements.

-

-

3D printing3D printing is used for new product development, which shortens the research and development cycle, saves the mold opening, and provides delivery guarantee for the research and development of new products cast by Haosen.

Mold manufacturingThe mold department is the first step in the production process of our company's products. The mold department currently has 27 people, and has complete processes such as design, process, turning, milling, grinding, CNC, three-coordinate, electric spark, wire cutting, fine boring, fitter, etc., which can fully independent the whole process of mold and tooling design and production assembly. Design and processing personnel experience, working time are more than 10 years. Manufacturing and production products, involving: precision casting molds, small blanking molds, rubber molds, plastic molds, parts processing tooling, measuring tools, aerospace supporting products molds and tooling.

Mold manufacturingThe mold department is the first step in the production process of our company's products. The mold department currently has 27 people, and has complete processes such as design, process, turning, milling, grinding, CNC, three-coordinate, electric spark, wire cutting, fine boring, fitter, etc., which can fully independent the whole process of mold and tooling design and production assembly. Design and processing personnel experience, working time are more than 10 years. Manufacturing and production products, involving: precision casting molds, small blanking molds, rubber molds, plastic molds, parts processing tooling, measuring tools, aerospace supporting products molds and tooling. Investment CastingsInvestment casting is one of the complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts.

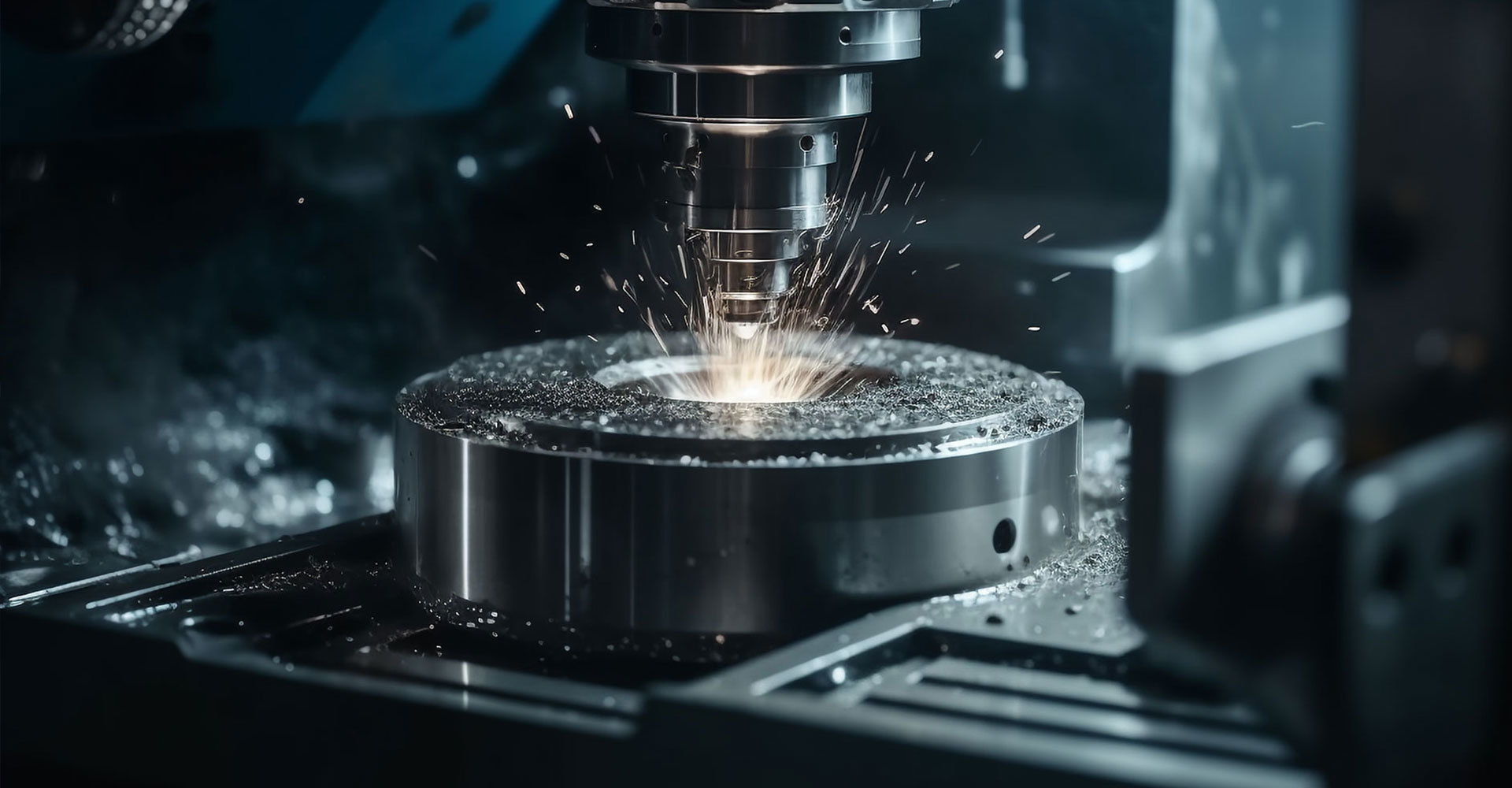

Investment CastingsInvestment casting is one of the complex casting processes, which can achieve high dimensional accuracy and surface quality while forming complex structures of parts. Precision MachiningPrecision machining is the application of production processes including turning, milling, boring, drilling, EDM, engraving, grinding and other processes, through mechanical processing to remove the material on the workpiece, the production of drawings with strict dimensional accuracy and shape tolerance and high surface quality of precision parts process.

Precision MachiningPrecision machining is the application of production processes including turning, milling, boring, drilling, EDM, engraving, grinding and other processes, through mechanical processing to remove the material on the workpiece, the production of drawings with strict dimensional accuracy and shape tolerance and high surface quality of precision parts process.

-

-

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

中文 | EN

FAQ

FAQ

QPrecision casting is also called investment casting

Sand casting production of casting precision, surface finish, material density and metallographic structure, mechanical properties and other aspects are often poor, so when the casting of these performance requirements are higher, should use other casting methods, such as investment (lost wax) casting, die casting, low pressure casting, etc., the following by the company editor for everyone to introduce:

Features and advantages of precision casting:

Precision casting, also known as investment casting, with other casting methods and parts forming methods compared to investment casting has the following characteristics:

1. The casting size precision is high, the surface roughness value is fine, the size precision of the casting can reach 4-6 grade, the surface roughness can reach 0.4-3.2 μm, can greatly reduce the machining allowance of the casting, and can realize the manufacturing without allowance, reduce the production cost.

2. Castings with complex shapes and difficult to process with other methods can be cast. The contour size of the casting is as small as a few millimeters to thousands of millimeters, the thinnest wall thickness is 0.5mm, and the smallest hole is below 1.0mm.

3. Alloy materials are not limited: such as carbon steel, stainless steel, alloy steel, copper alloy, aluminum alloy and high temperature alloy, titanium alloy and precious metal and other materials can be used in precision casting production. For alloy materials that are difficult to forge, weld and cut, it is especially suitable for precision casting production.

4. High production flexibility and strong adaptability. Can be used for mass production, but also for small batch or even single-piece production.

In summary, precision casting has the advantages of small investment scale, large production capacity, low production cost, simple process of complex products and quick investment. Thus, it is in a favorable position and has a bright future in the competition with other processes and production methods.

QWhat materials will be used in precision casting?

In precision casting, what materials are generally used?

In precision casting, we can use stainless steel, carbon steel, alloy steel, etc., which can be used for precision casting. However, it is still up to the specific situation to choose.

Precision casting, which can be referred to as precision casting, is a special casting method. Generally speaking, the parts obtained by precision casting do not need to be machined anymore, because it can obtain a more accurate shape and a higher casting accuracy. However, we can also heat treat and cold work the product according to its needs. The types of precision casting mainly include investment casting, pressure casting and so on.

QDevelopment Trend and Prospect Analysis of Foundry Industry

QWhat testing equipment is required for the foundry industry laboratory?

The foundry industry laboratory needs the analysis of molten iron carbon and silicon in front of the furnace or the analyzer of molten iron carbon and silicon manganese in front of the furnace, and the analyzer of the five major elements (chemical analysis). The analyzer of the five major elements is commonly known. In fact, the analyzer of the five elements can analyze many elements (C, S, Si, Mn, P, Ni, Cr, Mo, Ti, Cu, W, V, Σ RE, Mg, etc.); 4. Universal testing machine; 5. Hardness tester; 6. Ultrasonic flaw detector; 7. Box-type electric furnace (alias: muffle furnace) 8. Drying oven, etc.

QApplication of casting materials

Since the advent of the casting material, Baozhu sand has been widely concerned by the casting industry, and is widely used in resin sand (furan resin, phenolic resin), water glass sand (organic grease, CO2 hardening), and coated sand. It is suitable for various casting methods such as V method and VRH. Lost foam can not only greatly improve the casting quality, but also easy sand cleaning and simple and convenient sand mixing process (single piece and small batch of local sand in large steel casting plants can be mixed manually with a small amount of sand). For most castings, coating can be omitted, especially suitable for making castings with high quality requirements. The fluidity and filling property are good, and good formability and mold strength can be obtained. Good collapsibility, easy sand cleaning operation. Binder usage than other similar sand has greater savings. Low thermal expansion rate produces high dimensional accuracy of castings, few cracks and surface defects, and high yield of castings. Less casting production process of dust pollution to the production environment, good regeneration, reduce industrial waste emissions, conducive to environmental protection. Good fire resistance. Its application in lost foam casting has significantly improved the casting defects caused by traditional sand. There is a certain period of adaptation from quartz sand to jewel sand. After trying, some domestic enterprises have made many achievements in the application of jewel sand.

The high manganese steel castings produced by Jilin Innovation Lost Foam Equipment Co., Ltd. have a very serious phenomenon of sand sticking and sand inclusion before using jewel sand. It takes a lot of manpower and material resources to clean and polish the surface of the castings, which not only increases the production cost of the castings, but also causes the surface quality of the castings to be unsightly. This type of casting defect has been completely eliminated after the use of jewel sand. Cost savings of 6%.

Yulin Diesel Engine Factory uses Baozhu sand to make diesel engine water kit, which maintains the characteristics of the original sand, overcomes the shortcomings of large expansion coefficient of the original sand, large amount of binder, large amount of gas, etc., reduces the amount of resin added, and improves the yield of the product.

Dozens of manufacturers such as Luoyang Luobei Steel Plant, Ruyang Xingrong Machinery Plant and Shandong Hengcheng Foundry added 20-30% of 140-320 mesh fine sand to the jewel sand of 30-40 mesh sand. The results showed that the sand was also non-sticky, had sufficient air permeability and was easy to clean. In order to reduce the production cost, some steel casting plants adopt the method of local single-sided sand, which also plays the effect of non-sticky sand.

Address: No.28, Lantian 1st Road, National Aviation High-tech Industrial Base, Yanliang District, Xi'an City, Shaanxi Province

+86029-89080114 13630258521

Copyright©2023 Xi'an Haosen Precision Casting Co., Ltd.

Technical Support:China Enterprise Power Xi'an

SAF Coolest v1.3 设置面板 GAYSX-ZENJ-FFZQE-ZES

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page